- Products & Solutions

- XFdtd

- Circuit Element Optimizer

Circuit Element Optimizer

Determine component values for Full-Wave Matching Circuit Optimization (FW-MCO).

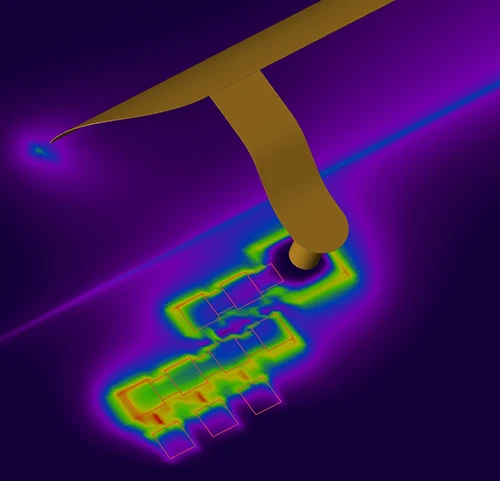

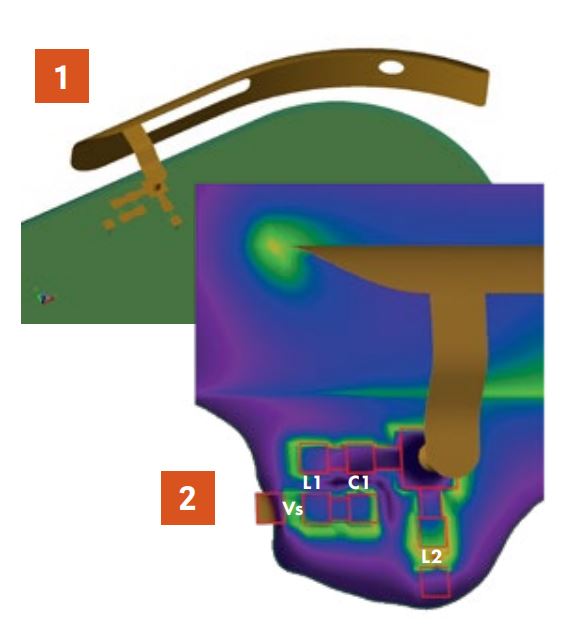

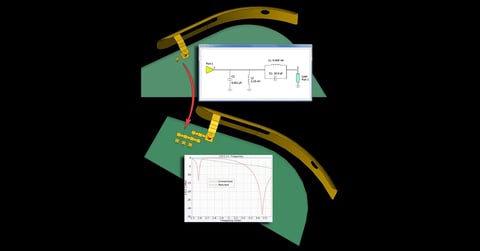

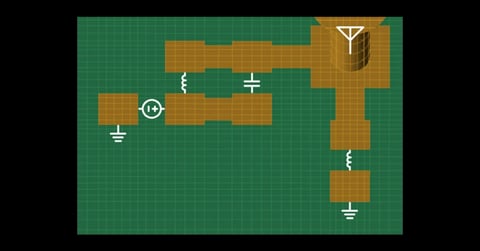

Full-Wave Matching Circuit Optimization (FW-MCO) is performed by XF's Circuit Element Optimizer. This capability selects the optimal component values for matching network layouts, printed circuit boards, antennas, filters, or other RF structures. Since the FDTD simulation method is used, the multitude of electromagnetic phenomena affecting the RF structure and components is accounted for, such as the coupling between the driven antenna and nearby copper traces.

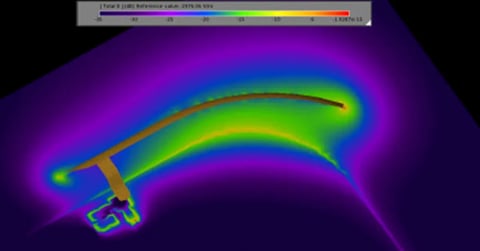

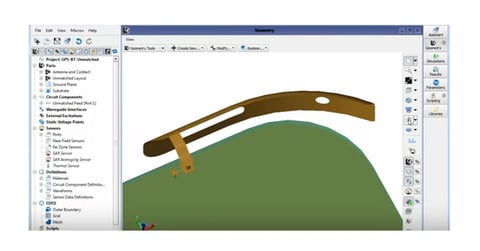

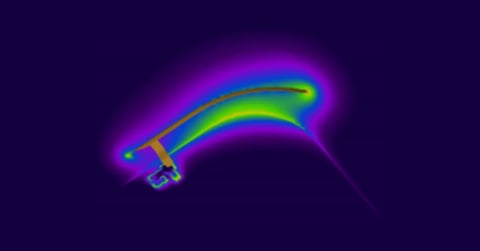

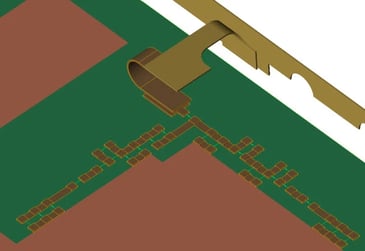

Matching network for a dual band antenna.

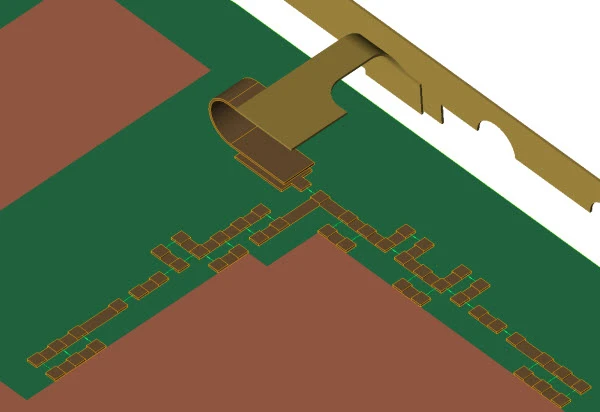

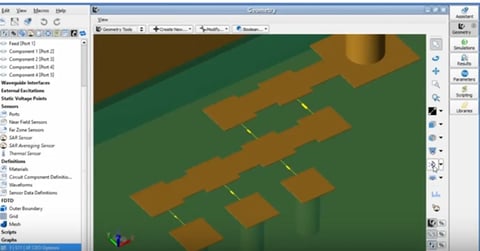

Circuit elements for optimization connect copper pads.

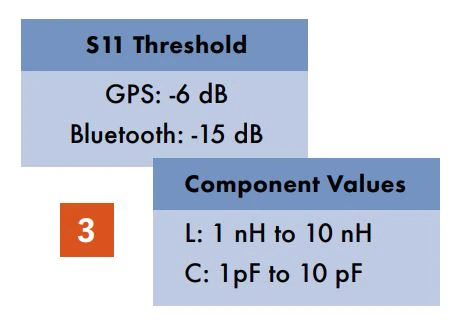

Goals and Component Values

The Circuit Element Optimizer characterizes the RF structure using full wave FDTD simulation, then selects optimal component values based on the following user defined goals:

- Radiation efficiency

- System efficiency

- S-parameters

Although traditional components include capacitors, inductors, and resistors, modern applications utilize more advanced components to achieve design requirements. The Circuit Element Optimizer supports the following types of components:

- Fixed resistor, capacitor, inductor

- Ideal resistor, capacitor, inductor

- Realistic capacitor, inductor with user-defined equivalent series resistance

- Standard *.s2p file definitions downloaded from component manufacturer

- Passive tunable integrated circuits (PTIC or “tuners”) in the MDIF format of *.s2p files

Each component can take on a discrete range of values, representing the parts available from a component supplier.

.webp)

Operating Modes

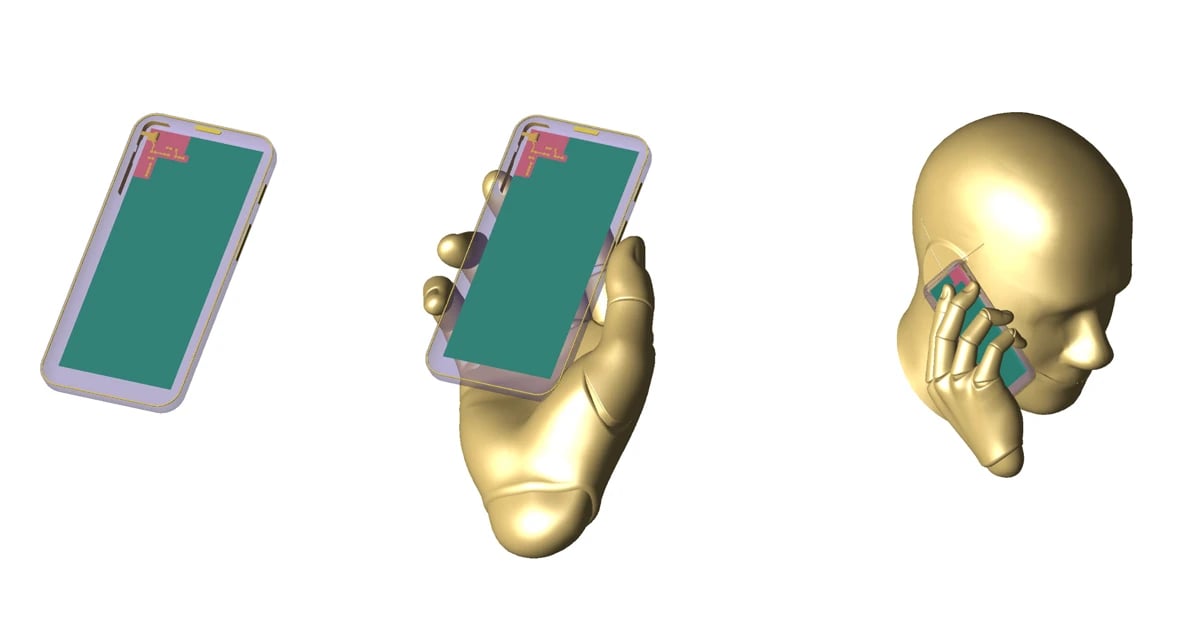

RF circuits are often used in different modes of operation, for example a mobile phone in free space versus one held in a hand. The Circuit Element Optimizer is able to recognize and consider multiple modes of operation when selecting component values. This results in tuner values that are optimized for individual modes and fixed L or C components that are best for all modes.

Design Flow with CEO

- Set up the XF project including copper traces, component locations, materials, grid, etc.

- Create a Response Matrix which uses FDTD simulations to characterize field interactions affecting the components.

- Perform a Circuit Optimization that uses S-Parameter and/or efficiency goals to select the optimal set of component values.

- . Verify that the matching network or filter performs as desired with the selected component values.

Additional Information

-

Webinars

Antenna Design Workflow Using Full-Wave Matching Circuit Optimization

The design of a matched antenna is a fairly involved process. This webinar shows how XFdtd simplifies this process by providing tools to parameterize the unmatched antenna, determine S11, synthesize a matching network topology with Optenni Lab, and determine the final component values using the Circuit Element Optimizer.

Explore Resource

Webinars

Introduction to XFdtd’s Circuit Element Optimizer

Remcom’s Circuit Element Optimizer for XFdtd is a unique tool for full wave matching circuit optimization. This webinar introduces the capability and provides an example of how it is used. A GPS/Bluetooth antenna and an LTE antenna are used for the demonstration.

Explore Resource -

Application Examples

FDTD Simulation: Optimizing an LTE Antenna's Matching Network

A simple antenna for LTE band operation is added to the PC board of a smartphone in XFdtd and the matching circuit is tuned for operation in multiple frequency bands. The component values in the matching network are chosen to maximize system efficiency.

Explore Resource

Application Examples

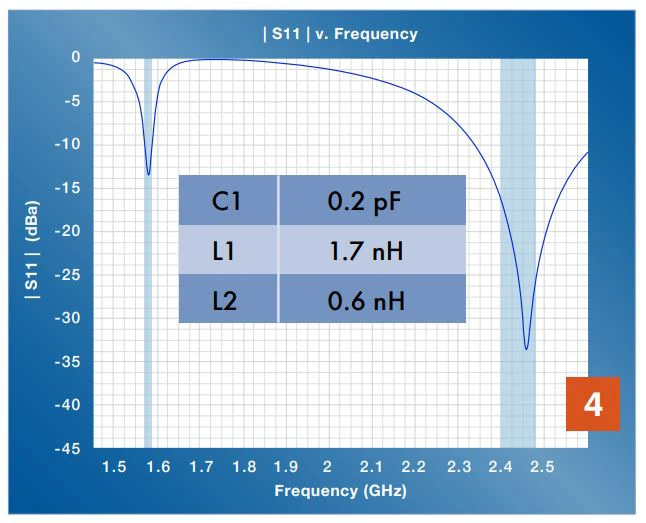

Full Wave Simulation: Matching Network Design for GPS / Bluetooth Antenna

XFdtd's Circuit Element Optimizer is used to determine optimal matching component values for a dual purpose antenna.

Explore Resource -

Videos

Demonstration of Full-Wave Matching Circuit Optimization in XFdtd

This video gives a demonstration of Full-Wave Antenna Matching Circuit Optimization using XFdtd's Circuit Element Optimizer (CEO). The antenna matching circuit design flow is discussed, including C

Explore Resource

Videos

XFdtd and Optenni Lab Integration for Matching Circuit Design

Remcom's XFdtd 3D EM simulator integrates with Optenni Lab for antenna matching circuit optimization. This brief video shows the highlights of the workflow and integration using a GPS and Bluetooth

Explore Resource -

Publications

Full Wave Matching Circuit Optimization Shortens Design Iterations

Full wave matching circuit optimization (FW-MCO) is a new technology that combines full wave, 3D EM simulation with circuit optimization into a novel approach for solving an age-old RF problem: determining which component values provide the desired match for a given matching network layout. This article describes the design process using the design of a matching circuit for a GPS-Bluetooth antenna.

Explore Resource

Publications

Overview of XFdtd's Circuit Element Optimizer

XF’s Circuit Element Optimizer utilizes full wave analysis to select the component values for a given printed circuit board (PCB) layout. The tool allows design engineers to optimize matching circuit lumped element values directly in the EM layout where the coupling from multiple antennas and the ground return current paths are taken into account. This whitepaper gives an overview of how the Circuit Element Optimizer works and the benefits it provides.

Explore Resource -

Brochures

Full Wave Matching Circuit Optimization Brochure

Determining the final set of component values in a matching network can be a challenging process. At higher frequencies, especially VHF and above, significant EM effects on the real circuit (inter-connection transmission line effects and coupling between the antenna being tuned, other antennas, and other parts of the structure) are difficult to quantify and account for in circuit schematic simulators alone.

Explore Resource

Save time and reduce costs.

Contact Remcom today for a customized solution to your most complex electromagnetic challenges.

Request a Quote